-

How are the devices worn?

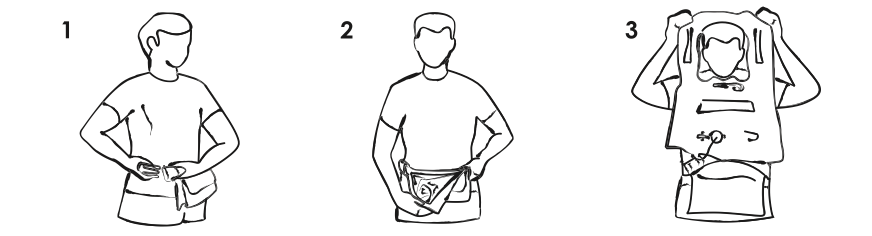

Wear the device like a normal jacket, ensuring that the central buckle is securely fastened then firmly tighten the waistband. If present, fasten and adjust the crotch strap.

For those in a pouch, wear the device like a normal belt with the pouch to the front and tightened firmly. To use, the chamber must go over the head before activation.

-

How is the device used?

Automatic/manual activators – inflation starts automatically within 5 seconds after coming into contact with water.

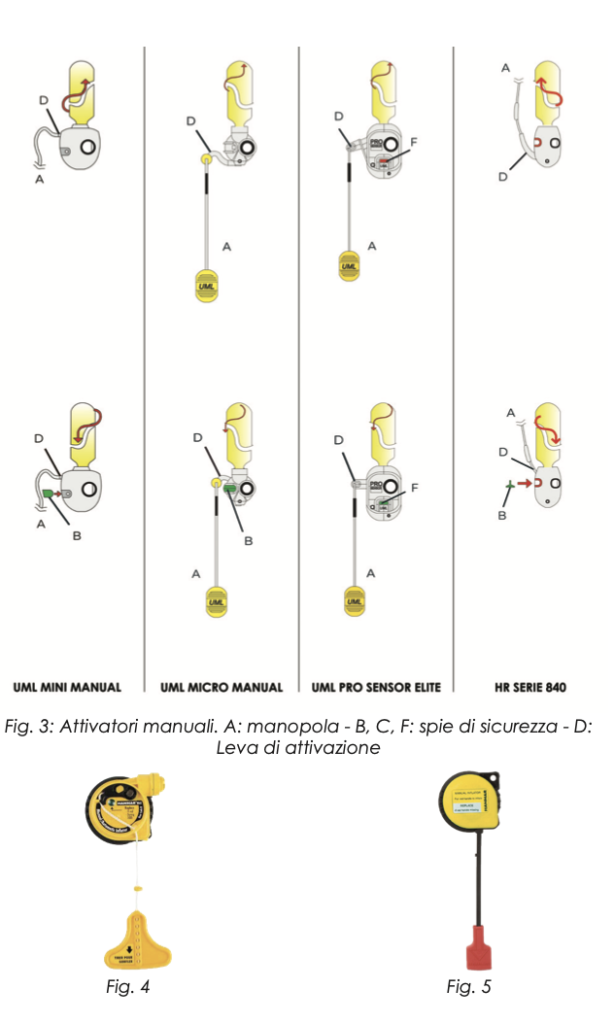

Manual activators only – inflating is done manually by firmly pulling on the knob on the outside of the casing.

Oral activation – the devise inflates by blowing into the red tube to the left of the chamber. Open the case of the device, locate the tube and blow into it. The tube is fitted with a non-return valve and protective cap.

-

Should I check the device before use?

CHECKS BEFORE USE

Conduct a visual inspection to determine there is no damage. It is advisable to also check the integrity of the CO₂ canister. If in doubt, open the housing and carefully examine the inner tube.

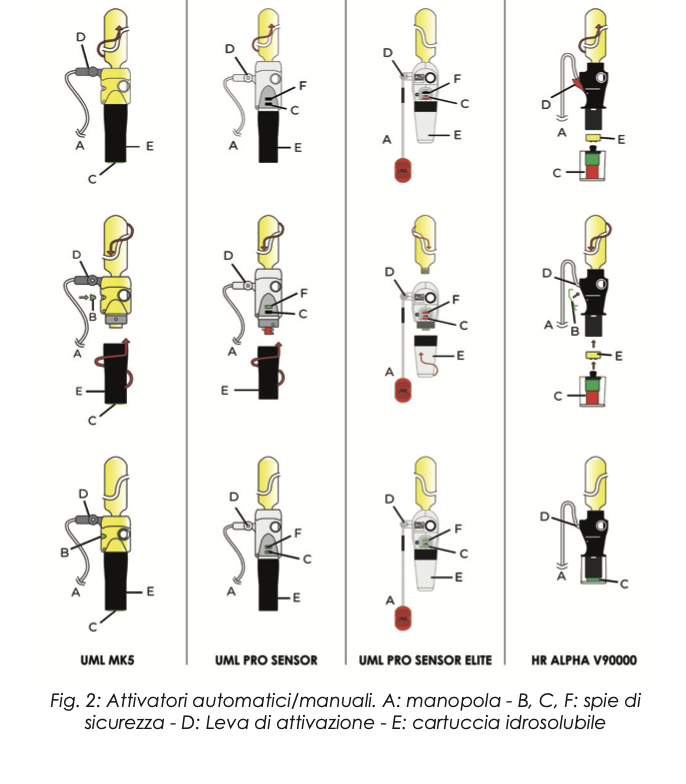

Check that the cap on the mouth tube closes the tube itself. Ensure that the safety pins and lights are green, if present on the activator (for the HAMMAR activator, please refer to the enclosed manual).

To avoid accidental activation during transport, the knob should be inside the case, ensuring that it is accessible when the jacket is worn.

-

How do you reactivate a jacket after use?

RESTORING THE DEVICE

PLEASE NOTE: Only by sending the device and its technical characteristics to an Authorised VSG Inspection Station can the most correct restoration procedure be guaranteed.

The jacket must be put away only once the device is perfectly dry.

Before reactivation, the device must be deflated by inserting the protective cap into the oral inflation tube in an upside-down position, applying pressure to the chamber to release all the air. If necessary, roll up the chamber to allow the air to escape. Repeat the operation at least once to ensure that all the air has escaped then close the tube with the cap.

Rinse the device and follow the directions for CARE, MAINTENANCE AND INSPECTION. If the device has been used without automatic activation, remove the canister and the cap with the water-soluble cartridge before cleaning.

Reactivation for devices having an automatic activator with water-soluble system:

Remove the canister by unscrewing in an anti-clockwise direction

1) Ensure that the lever is in the home position.

2) Apply a new protective clip if present on the supplied activator.

3) Unscrew and remove the cap with the water-soluble cartridge.

4) Replace the cartridge, screwing it in tightly. Check that the cartridge safety light is green.

5) Ensure that the firing pin does not protrude into the canister housing.

6) Replace the canister, checking that it is well sealed, screwing it fully clockwise. If present on the supplied activator, check that the safety light F is green.

Reactivation for devices with a manual activator:

Proceed as above, skipping Steps 4 and 5.Reactivation for devices with a HAMMAR hydrostatic activator:

Reactivation for devices with a HAMMAR hydrostatic activator:

Follow the instructions in the HAMMAR manual enclosed with the device. If the manual has been lost, the instructions can be found through the VSG offices or by visiting www.veleriasangiorgio.com.

FOLDING UP:

After completely deflating the chamber (as per the previous paragraph) and making sure that the device is perfectly dry, lay the chamber on a clean, smooth surface and fold it into the case.

Take care never to roll the chamber inside the case but to proceed by folding it up on itself. During the process, ensure that activation knob A is positioned towards the outside of the case. Close the case by securing the Velcro edges or closing the zip, if present.

PLEASE NOTE: To open and close the zip, if present on the case, never proceed as with a normal zip – after completely separating the two parts of the zip, starting from the highlighted easy-open point, return the slider to the starting point and close it again.

-

What spare parts should I buy to reactivate the jacket?

Visually check the model of activator used on your jacket, identify the type of water-soluble tablet and the weight of the CO₂ canister. Select the spare parts according to the technical specifications of your device.

-

Where can the device be stored on board?

Store the device in a dry and ventilated place since

moisture can penetrate within and cause activation. The device has been tested to operate between -30° C and 60° C, however prolonged exposure to very low temperatures can cause incomplete inflation, in which case it is likely that inflation will have to be done via the blowing tube.

-

Can this device replace a rigid jacket?

Yes, provided it is of a class and certification suitable for the type of vessel and navigation undertaken

-

Is it a compulsory piece of equipment to have on board?

Yes, as long as the device is equipped with automatic activation and meets the minimum buoyancy required for the type of navigation.