After use and activation of the device, it is recommended to contact an Authorised VSG Inspection Station to have it restored.

The following steps can be performed to restore the device:

- Deflate the device as described in the previous section and rinse in fresh water. Do not use solvents or detergents to clean any traces of oil or dirt – only utilise a solution of fresh water and mild soap. Do not use a washing machine or dryer nor spin-dry. For use without the activation of an automatic device, remove the canister and water-soluble cartridge prior to cleaning. After washing, allow the device to air dry completely, out of direct sunlight.

- Check the chamber and/or housing for damage or signs of excessive abrasion that could cause malfunction.

- Check the integrity of the straps, buckles, seams and zips, if present.

- Check the seal of the chamber by fully inflating it and examining the device after 12 hours.

- Replace the water-soluble cartridge each year in the case of professional use of the device or every 2 years for recreational use. The water-soluble cartridge must not be more than two years old at the time of purchase.

PLEASE NOTE: During maintenance operations, in the event of damage, air leaks, malfunctions or breakages, do not attempt to repair or modify the device but contact an Authorised VSG Inspection Station immediately.

The quality, care and maintenance of the safety device components are vital in limiting their normal deterioration over time. On the label applied to the product, there may be instructions and advice on the time limit within which the characteristics of the products remain unchanged.

STORAGE AND USAGE ENVIRONMENT

Store the device in a dry and ventilated place since moisture can penetrate within and cause activation.

The device has been tested to operate between -30° C and 60° C, however prolonged exposure to very low temperatures can cause incomplete inflation, in which case it is likely that inflation will have to be done via the blowing tube.

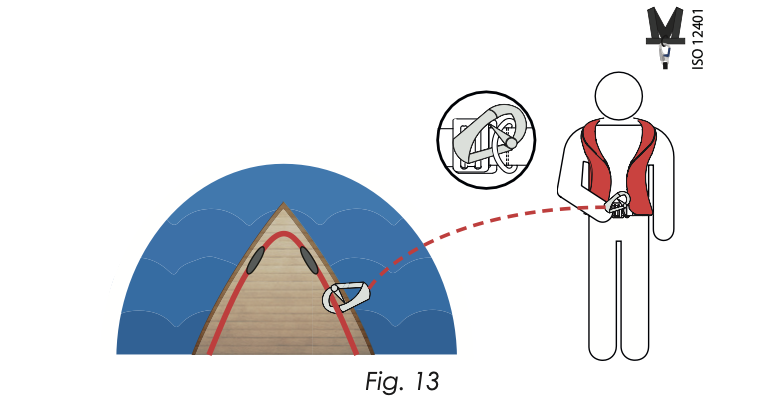

These devices can be used with any integrated safety line, of which VSG offers a broad selection in the catalogue.

However, it is important to bear in mind that which follows.

- Jackets with an integrated harness or safety line are designed to prevent falling overboard but not to protect against falls from a height.

- The integrated harness and safety lines can result in harsh recoil and must be anchored to robust coupling points.

- INSPECTION

The manufacturer VSG recommends that the first inspection be carried out within 24 months from the date of purchase and in any case, within 36 months from the date of manufacture, whilst subsequent revisions should be carried out at least every two years. Inspections must be conducted at Authorised VSG Inspection Stations.

The Authorised VSG Inspection Station will fill out the service label attached to the product (Image 14) and fill in the date on the jacket (Image 15) with the date of the next inspection. An Inspection Certificate will also be issued, listing the operations carried out.