VACUUM TECHNOLOGY

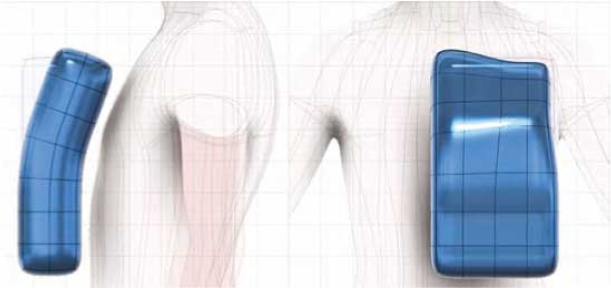

The advantages of an inflatable life jacket (GDSG) compared to a rigid jacket (FOAM) are many. These include increased portability and safety, derived from the ergonomics and the form of the floating chambers, which shorten the time it takes for a castaway’s body to rotate in the water. This also favours less storage space being required.

Despite such factors, the biggest obstacle to deploying Solas GDSGs on cruise ships is the cost of inspection at the service stations in ports which, according to regulations, must take place every 12 months.

To avoid this impediment, VSG presented and successfully tested the first Authorised On-Board Inspection Station set up on a ship, also dedicated to the implementation of the GDSG SOLAS VACUUM, an innovative product that enables an overhaul programme to be completed on a five-year basis.

This renders it possible to reduce product shipping, delivery and collection costs to zero, whilst also optimising personnel costs given that the staff who complete the inspection is already on board, having been trained by our technicians who are nonetheless always available for remote assistance.

This solution thus proves to be an advantage for everyone, facilitating savings on costs but not on passenger safety.